Glass Reactors

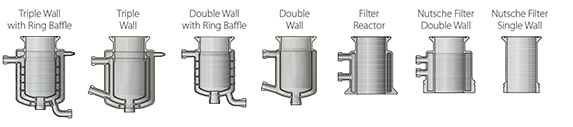

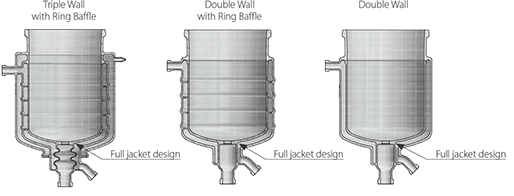

-Triple Wall with Ring Baffle, Triple Wall, Double Wall with Ring Baffle, Double Wall, Single Wall

- From 300 mL to 400 L (Single Wall, Customized product)

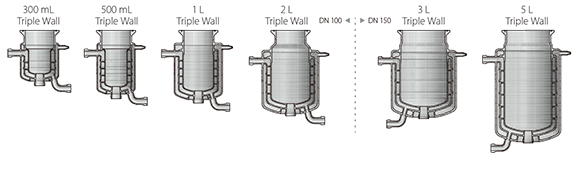

Reaction Unit, Bench-top : 300ml, 500ml, 1L, 2L, 3L, 5L

Variety of Vessel Options

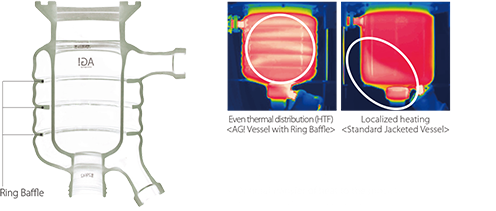

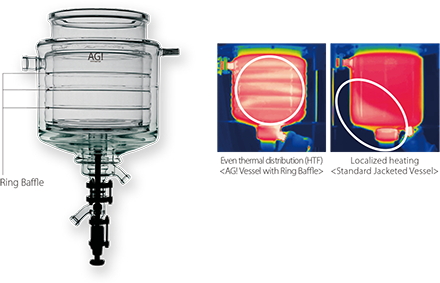

AG! Proprietary Ring Baffle Technology

AG! Glass Ring Baffle guides the flow of heat transfer fluid to prevent hot and cold spots and provide even heat distribution.

• Optimizes heat transfer to the internal vessel

• Provides uniform and efficient temperature control in the process

Interchangeable Scale-up

Scale Up from 300 mL to 2 L and 3 L to 5 L made easy by simply changing vessels.

* DN 100 Vessel Clamp for 300 mL to 2 L

* DN 150 Vessel Clamp for 3 L and 5 L

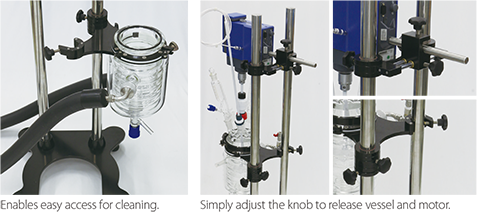

Vessel Arm Swing

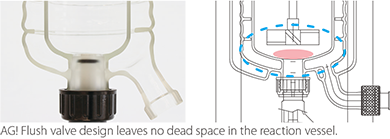

Leak-proof Flush Valve

Pressure sensitive spring loaded flush valve prevents leakage.

Easily removal for cleaning.

Zero Dead Space

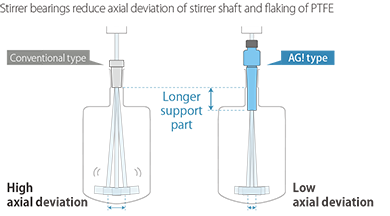

Reduced Vibration and Flaking

Newly designed AG! Stirrer Guide reduces axial deviation of stirrer shaft and flaking of PTFE.

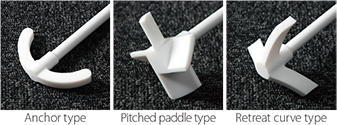

Impeller Options

Reaction Unit, Pilot-plant: 10L to 100L (Double-Walled:10L,20L,30L,50L.100L, Triple-Walled:10L,20L,30L,60L)

Precise and efficient temperature control, minimum energy loss can be realized using our Reaction Vessel.

Variety of Vessel Options

AG! Proprietary Ring Baffle Technology

AG! Glass Ring Baffle guides the flow of heat transfer fluid to prevent hot and cold spots and provide even heat distribution.

• Optimizes heat transfer to the internal vessel

• Provides uniform and efficient temperature control in the process

Easy Scale Up

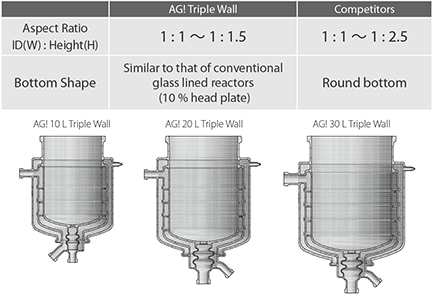

Our triple Wall reactors are designed to keep the ID (W) width and (H) height ratio within 1 : 1 to 1 : 1.5 for structural integrity, performance and easy scalability.

Unique Flush Valve Minimizes Dead Space

Impeller Options

Reaction Unit, Pilot-plant Fully Functional Stand: 10L, 20L, 30L